Electric-powered Steam Generators: The Cornerstone of Modern Manufacturing

In the current fast-paced manufacturing landscape, efficiency and dependability are essential. vaporrey.com across various industries are constantly looking for innovative solutions to improve efficiency and minimizing running costs. A single particular solution that has achieved notable popularity is the electric steam generator. These powerful units have turned into the foundation of modern industry, serving a vast array of uses with exceptional efficiency and safety.

Electrical steam generators offer numerous benefits that distinguish them from traditional steam producing methods. Their ability to generate instant steam, coupled with accurate control over pressure and heat, enables industries to function with greater flexibility. As companies shift toward more sustainable methods, electric steam generators also play a vital role in lowering carbon footprints and energy use, making them an integral component in the transition towards cleaner solutions.

Types of Electric Steam Generators

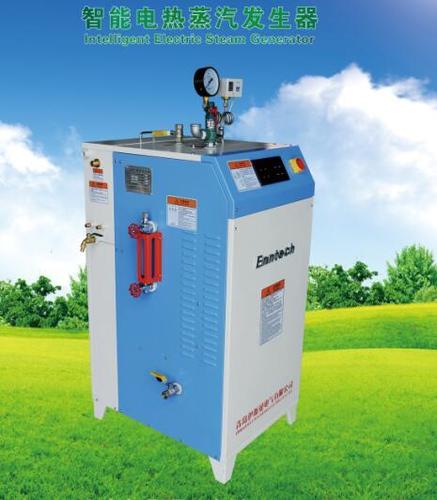

Electric steam generators come in different types, designed to cater to specific industrial needs and applications. One frequent type is the electrode steam generator, which operates by using electrical resistance to generate steam. These units are known for their quick response times and compact size, making them ideal for tasks that require instant steam generation. They are particularly effective in medium to low-pressure applications where smaller steam quantities are needed.

An additional prevalent type is the electric heating boiler, which utilizes electrical energy to heat water and produce steam. Electric boilers are adaptable and can be found in both low and high capacity settings, making them suitable for a diverse of industries, from food production to medicines. Their ability to integrate seamlessly with existing systems allows for efficient operation and minimized emissions, aligning with modern sustainability goals.

Moreover, there are modular electric steam generators, which offer flexibility and scalability for industrial operations. These units can be connected to meet fluctuating demands and provide a consistent steam supply without the need for extensive infrastructure. Modular generators are notably beneficial in industries that experience changing steam requirements, ensuring constant efficiency while reducing downtime and service expenses.

Advantages of Electric Steam Generators

Electric steam generators deliver a multitude of benefits that position them an optimal choice for numerous industrial applications. One of the primary advantages is their efficiency. Unlike traditional steam boilers that rely on fossil fuels, electric steam generators change electrical energy directly into steam with minimal heat loss. This results in more rapid steam production and diminishes the overall energy costs, thus making them considerably economical in the long-term.

Additionally, significant advantage is their compact design and ease of installation. Electric steam generators are usually smaller and lighter than conventional boilers, facilitating flexible placement in facilities with tight space. Their straightforward installation process means that be up and running swiftly, which is particularly valuable for businesses that demand immediate steam availability for continuous operations. This ease of integration into current systems is a critical consideration for modern industries.

Lastly, electric steam generators are green friendly. They produce no emissions during operation, contributing to a cleaner workplace and lowering the carbon footprint of industrial processes. Additionally, numerous these generators can be powered by renewable energy sources, which further enhances their sustainability. As industries increasingly prioritize eco-friendly practices, electric steam generators are notable as an attractive option for those seeking to innovate while lessening environmental impact.

Implementations in Various Sectors

Steam generators play a critical role throughout a varied range of sectors, demonstrating their flexibility and effectiveness. In the food and drink sector, these generators provide consistent steam for processes such as pasteurization, sanitization, and processing. The uniform and controllable steam produced ensures that food items meet safety regulations while preserving quality. This trustworthiness is important in an field where cleanliness and precision are paramount.

In the drug industry, electric steam generators are indispensable for sterilizing equipment and ensuring the production of secure medications. The generators provide steam that meets stringent quality standards, vital for preserving sterile conditions. Additionally, the ability to quickly adjust steam output allows pharmaceutical manufacturers to enhance their processes, reducing downtime and increasing overall efficiency.

The fabric industry also edges significantly from electric steam generators. They are used for multiple processes, including tinting, treating, and fabric care. The precise temperature control and consistent steam delivery ensure that textiles are handled uniformly, resulting in higher quality goods. Moreover, the power efficiency of electric steam generators helps textile manufacturers cut operational costs, making them a popular choice in this challenging market.